Miles Fiberglass attended the Pacific Northwest Defense Coalition Supply Chain Conference yesterday. It was a great day and valuable opportunity to network with professionals in our industry, learn about new developments and trends, and gain insights that can help improve our own work.

This was a great opportunity to learn from others who have faced similar issues and to share best practices and strategies for addressing common challenges.

We were asked, “Were there any specific issues or challenges that were discussed at the PNDC conference that you found particularly interesting or relevant to Miles?” Learning about how others in your industry have addressed these challenges can be valuable in helping you develop your own approach to managing your supply chain.

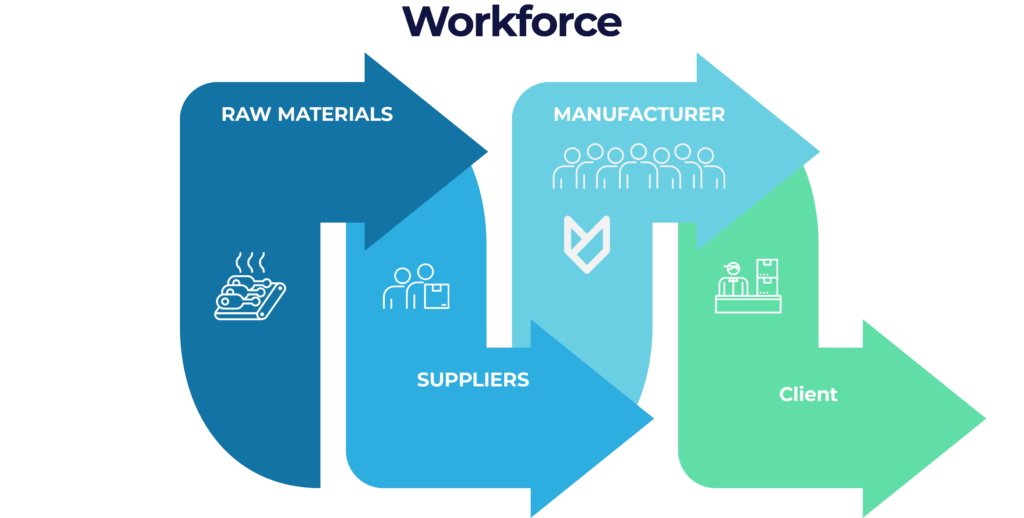

Work force attendance was one of the takeaways and common themes.

Here is our insights.

Employee engagement and attendance can be a significant challenge for many organizations, and it’s not surprising that this was a common theme at the PNDC Conference. There are many strategies that organizations can use to improve employee engagement and attendance, including:

Clear communication: Ensuring that employees understand their roles and responsibilities, as well as the goals and expectations of the organization, can help them feel more engaged and motivated. Regular communication and feedback can also help employees feel more connected to their work and the organization.

Employee recognition: Recognizing and rewarding employees for their hard work and achievements can help boost morale and motivation. This can include both formal recognition programs, such as awards and bonuses, as well as informal recognition, such as public praise and thanks.

Training and development: Offering opportunities for employees to learn and grow within their roles can help keep them engaged and motivated. This can include on-the-job training, professional development programs, and mentoring and coaching.

Work-life balance: Providing flexibility in scheduling and time off can help employees better manage their personal and professional lives, which can lead to improved engagement and attendance.

Employee wellness: Supporting employee health and wellness can also help improve engagement and attendance. This can include offering wellness programs, providing healthy snacks and meals, and encouraging physical activity.

By focusing on strategies like these, organizations can help improve employee engagement and attendance, which can ultimately lead to better outcomes for the business as a whole.

“What is one weakness your company has that other manufacturing companies are doing well?” At Miles, we feel we could use a little help on production tracking. Here is our takeaway on production tracking:

Implementing a system for tracking production in progress using barcodes or a similar technology is a common practice in many manufacturing and supply chain industries. Such a system can provide real-time visibility into the production process, enabling better decision-making, more efficient workflows, and improved quality control.

There are various technologies and solutions available for implementing a production tracking system using barcodes, such as barcode scanners and printers, mobile devices with barcode scanning capabilities, and software applications that enable the capture and analysis of barcode data.

When implementing a barcode-based production tracking system, it’s important to consider factors such as the size and complexity of the production process, the types of products or materials being produced, the existing infrastructure and IT systems in place, and the needs and preferences of the workforce. It’s also important to ensure that any system implemented is compatible with existing enterprise resource planning (ERP) systems and other critical business systems.

Overall, implementing a barcode-based production tracking system can provide significant benefits in terms of improved production efficiency, better quality control, and greater visibility into the production process. It’s worth exploring the available options and working with a technology provider or consultant to determine the best approach for your organization’s specific needs and requirements.

If you find your company in this situation or can relate let us know.

Share:

Get notified about what’s new